Zgdh-f-ii intelligent sliding switch

This switch is a new device used to detect the belt speed of conveyor, and it can detect the belt speed in real time. It has been widely used in the belt conveyor system, providing a reliable detection method for the safe operation of belt conveyor.

It is necessary to install it horizontally on the conveyor bracket between the ascending belt and descending belt, so that the contact wheel and the belt surface have certain pressure to prevent the wrong action caused by the contact wheel jumping.When the contact wheel moves with the belt conveyor and drives the pulse disk inside, the magnetic signal of the sensor should be input into the control circuit when the pulse is rotated, amplified, and then counted.The calculation value is compared with the pre-value number to determine the belt number of the tape, i.e., normal speed, skidding or overspeed, etc.At the same time, the execution circuit outputs the corresponding switch signal.

Structural features

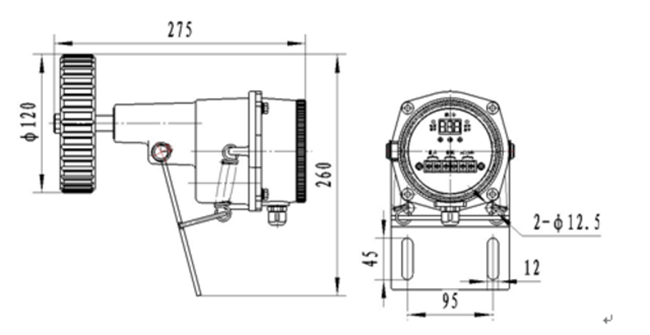

This machine is composed of contact wheel, pulse disk, electronic pulse switch, shell and so on. The contact wheel is made of aluminum, the surface milling groove is wear-resisting and slippery.

The internal switch of the machine is normally on and off independently. If the belt speed is lower than the set speed, the switch can trip or stop (generally, the set value is 70% to 80% of the normal value).

I. technical parameters

Power supply voltage: AC220V detection range: 0.5m/s ~ 9.99m/s

Pulse pulse: 6 ~ 120Hz speed: 0 ~ 999 RPM

Startup delay: 0-60 seconds adjustable (factory setting: 10 seconds) switch and target distance: 10-20mm

Action delay: adjustable from 0 to 60 seconds (factory setting: 001 seconds)

Number of switches: 1 set of normally open and 1 set of normally closed

Contact capacity: 24 ~ 380V AC/DC current 1A

Detection indicator: when the speed range is within the set range, the relay output and LED light will help detect the sensor or check the wiring fault

English

English Español

Español Русский

Русский עברית

עברית Français

Français

Product quality protection

Product quality protection