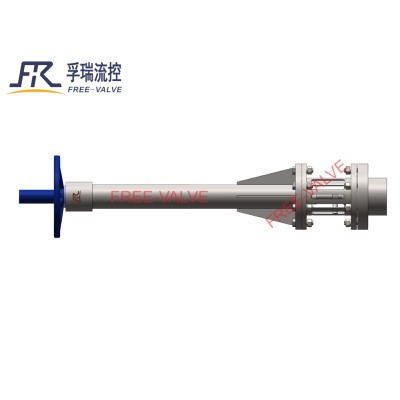

FREE-Valve’s manual operation Tank Bottom Valves with Strainer are designed for the convenient and fast discharging drilling mud or samples from the bottom of the reactor,drain or feed vessel.The valve can be welded or installed on the vessel through the flange at the bottom of the valve , tank bottom valves are most commonly installed on feeding of vessels or dead space free draining. This valve is operated on the top of the tank, in contrast to other discharge valves operated on the bottom of the tank.

Features

1.The valve body is provided with strainer as the valve inlet,the valve body is immersed in the medium,the filtered medium enters the tank through the strainer.

2.Structures with disc opening into the tank and disc opening into the valve.

3.A rotation-resistant device is set up to ensure that the valve stem only has straight line motions and no rotation.

4.The sealing surface of the valve seat and the valve disc is made of over laying cemented carbide or painted with tungsten carbide. The auxiliary line sealing guarantee the reliability of the sealing performance.

5.Stem packing seals are installed inside the valve body to prevent medium from running through the stem to the outside, while protecting the valve stem from cleaning.

Technical Parameters

Flange connection ASME B16.5,GB/T9113

Design standard ASME B16.34

Pressure Range Class150,PN10,PN16

Size Range DN50~DN 350, NPS2~NPS14

Material Carbon steel, stainless steel

Connection type Flange

Working Temperature ≤425℃

Operating Type Pneumatic, manual, electric

Sealing surface material Alloy,Carbide,other material

Pressure test GB/T13927, API598

Applications

FREE-Valve’s Tank Bottom Valves(with Strainer) are widely used in drilling mud, the petrochemical industry,alumina industry,steel industry,polymer,mining industry,the pharmaceutical and fine chemicals, and mineral processing industries.

English

English Español

Español Русский

Русский עברית

עברית Français

Français

Product quality protection

Product quality protection