Product Description

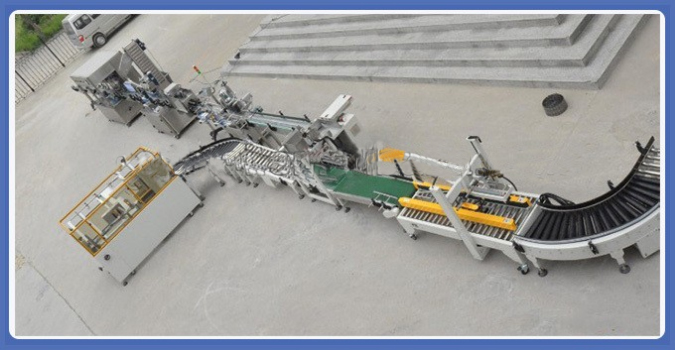

This main machine is mainly used for filling packaging various bottled oil, liquid type products, Now it is made of filling machine, labeling machine, coding machine,shrinking packaging macine, unpacking machine, sealing machine.

Certainly, this is belong to forepart packing, ceertainly if you need the whole packaging, we could do it as well.

Principle and Features of Main Machine ( Plastic Bottle Production Line )

A, Plastic Bottle Production Line is automatic quantitative liquid filling machine, suitable for filling all kinds of oils, such as lubricating oil, edible oil filling, etc.

B, The model of Plastic Bottle Production Line is equipped with touch-screen, 8 meters Frequency belt, auto-sensing-based sealer, vacuum anti-drip device

C, Plastic Bottle Production Line has a beautiful shape, a high filling precision, convenient adjustment and easy to operate.

D. Man-machine interface, directly set the filling volume;

E. PLC program control, inverter adjust the speed ,filling in line;

F. High-precision positive displacement flowmeters, quantitative accurate and reliable;

G Mechanical seals plus vacuum suck back mack a double anti-drip;

H. Quiklly at first and slow down after ,the double-flow speed make more accuracy effect.

Filling product line include:main filing engine + 8 m chain plate conveyor(stainless steek) + automatic induction sealer

Filling Machine Type | Automatic Filling Machine with Eight Heads |

Filling Heads | Eight Heads |

Filling Speed | 1800b/h-2000b/h |

Filling Range | 1-5L |

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

Beverage bottle, cosmetic bottle, medicine bottle, jar etc.

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.

Parameters of Capping Machine (The following are for reference.)

Production capacity | 2000B/H, 5000B/H, 7000-8000B/H |

Diameter of bottle | φ50-φ100, φ50-φ100, φ50-φ100 |

Height of bottle | 150-320mm, 150-320mm, 150-320mm |

Power | 0.75kw, 2kw, 1.2kw |

Overall dimensions | 900×700×1850mm, 1200×1000×1800mm, 1500×1200×1900mm |

Weight | 350kg, 500kg, 750kg |

Labeling Part --Labeling Machine

Mainly applied to food, grain and oil industries in the square, round bottle-shaped materials, demand for fast automatic labeling, such as: flat bottles labeling, square bottles labeling, with matching oil production line labeling. With the general good, high stability, durability and so on.

Labeling Machine Features

1. A unique sub-material bodies, to ensure that the production line on-line use of reliable and effective sub-material.

2. A unique corner of Fu-standard institutions to ensure that the side corner of square bottles labeling three flat, non-wrinkle

3.Labeling Machine is not only stand-alone used, but also used in conjunction with the production line.

Specifications of Labeling Machine

1. Material Dimensions: (round bottle) diameter Φ80-Φ150mm; (Square bottle / flat bottle) Length 100-180mm, width 80-180mm, bottles of 50-350mm

2. Labeling speed: Square bottle side / corner of labeling (in 5L bottle square meter): 45 bottles / min

3. Positioning Leaflets labeling round bottle (round bottle with 1.8L total): 35 bottles / min (with the materials and label size related)

4. Labeling accuracy: side labeling position error ≤ ± 1.5mm

5. Round Bottle Labeling weeks to locate position error: ≤ ± 2.0mm

6. Beginning and end error difference: ≤ ± 1.5mm (excluding packaging and labeling pieces of error)

The computer industrial inkjet printer, using the UK Coding technology, For food, medicine, chemical industry, beverage, cosmetics, electronics components and building materials industries play a date code, shelf life of Coding, is the choice of a mass production line.

Main structural characteristics of Coding Machine

1. The introduction of the new British Coding ink-drive system with built-in pump

2. The industrial inkjet printer changes to the content of lead in achieving online

3. The industrial inkjet printer is the first to use large print head input method

4. On-line print three lines of numbers in Chinese and English

5. High-speed printing for a variety of materials, can automatically edit the graphic

Specifications | Specifications of Coding Machine |

Print numberof rows | 1-3 line |

Font Height | 1.2mm-12mm |

Print speed: | 2m / s |

Print direction | 360 degrees |

Print content | Chinese, English, Arabic, picture |

Operating Humidity | 220V ± 10% VAC, 50Hz |

Dot Size | 5 * 77 * 9 12 * 12 16 * 16 24 * 24 |

Print format | positive and negative, reverse, back reverse, |

Samples bottles, Suitable for various bottles, No bottle No filling, Perfect Packing

Samples bottles, Suitable for various bottles, No bottle No filling, Perfect Packing

Detailed Images