--17852571959

High Quality Coal Slag Crusher

Details

model | Scm800 | Scm900 | Scm1000 | Scm1250 | Scm1680 |

Main motor | Power75 | 45*2 | 132 | 185 | 315 |

Analytical engine(FM motor) | Power18.5 | 18.5 | 30 | 15*4 | 18.5*5 |

Blower motor | Power45 | 55 | 75 | 55*2 | 90*2 |

crusher | Model pc 400*600 Power18.5 | Pc 400*600 18.5 | Pc 400*600 18.5 | Pc 600*800 45 | Pc 600*800 45 |

elevator | Model th-200 Power3 | Th-200 3 | Th-300 4 | Th-300 5.5 | Th-300 7.5 |

Vibrating feeder | Model300*60*1.8Φ159-1.8 Power1.5/3 | 300*60*1.8Φ159-1.8 1.5/3 | 300*60*1.8Φ159-1.8 1.5/3 | 400*80*2Φ219-2 1.5/3 | 400*80*2.8 2.2 |

Discharge screw conveyor | Model ls219-4.5/ls219-3 Power3 | Ls219-5.8 3 | Ls219-6.9/ls219-5 4 | Ls219-5 3*2 | Ls273-8.6 5.5*2 |

Discharge valve | Modelzid-200 Power0.75 | Zid-200 Zid-250 0.75+1.1 | Zid-200 Zid-250 0.75+1.1 | Zid-250 1.1

| Zid-300 Zid-200 1.5+0.75 |

Pulse dust collectors | Modeldmc120/dmc16 | Dmc16 | Ldmc25 | Ldmc45 | Ldmc400*2 |

Air compressor | Modelks150d/lg1.5-8 Power11 | Ksh240d/lg2.4-8 15 | Ksh300d/lg3.6-8 22 | Lg6.2-8 37 | Lg10-8 55 |

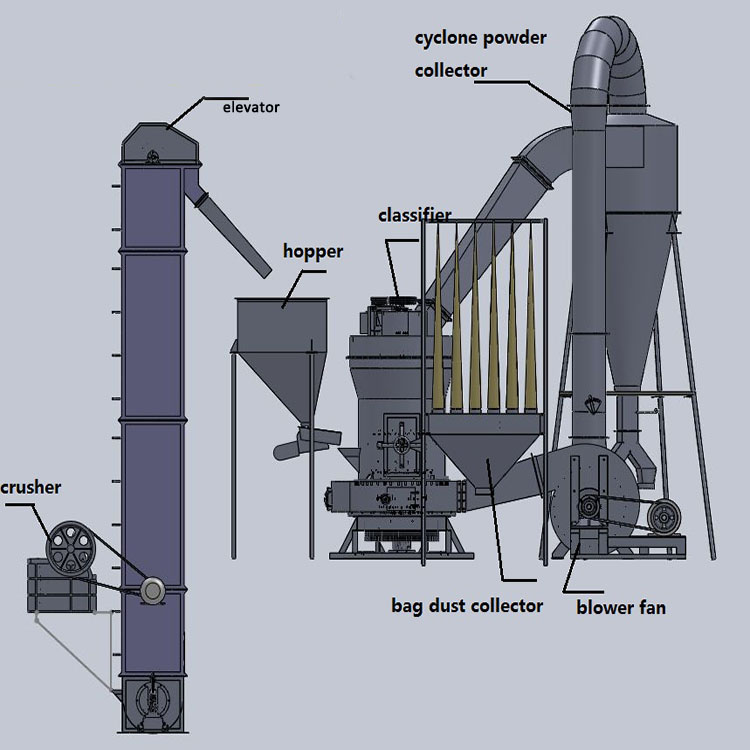

both diesel and electric drive cinder powder grinding mill consists of host, blowers, ultrafine analysis machine, finished products cyclone collector, bag-type dust collector, connecting pipe and other components.

SCM series both diesel and electric drive cinder powder grinding mill is developed. Its powders’ fineness can be adjusted within a range from 325 to 2500 meshes and its disposable fineness can reach D97≤5um which has ranked the leading level in the same trade and partial highest fineness reaching 2500 meshes through repeated experiments test by the geoscientific research institute. Because of its good performance, SCM win high praise from the users.

1) Eight years of manufacturing expenrience in the field of general machineries and we have our own export right.

2) Professional engineers and test equipments to ensure the quality of each machine.

3) Factory direct selling at competitive prices.

4) Good parts assembled, strictly quality control system.

YantailongkouGroup Work Win Supply Chain Co., Ltd. is a leading manufacturer and provider of total integrated supply chain solutions. We offer the best chemical products for the orders.

We have a multilingual team, and many big branch factories. A regional market presence-including southeast Asia, Indonesia, Russia, Spain, Chile, Brasil, Australia etc.

Group Work Win strives to build a long term relationships by providing our customers with continuous and reactive support. We aim to supply better quality products and after-sales service.

Visitors

Visitors

1. what is the raw material do you want to process?

A:Such as Dolomite 、Calcite、Quartz、Basalt 、Barite 、Feldspar.etc.

2. what is the capacity per hour do you need?

A:Such as 0.5-1000TPH.

3. what is the raw material input size?

A:Like 0-10,15-20mm for crushing 0r 75 microns(200meshes) for grinding mill machine and other requirements.

E-mail:harold@groupworkwin.com

Tel:18863695178