Product Background:

Traditional plant fiber extraction methods rely on manual operation, such as the method of peeling, rod removing, beating and other series of steps, and the method of extracting the plant fiber by chemical immersion. The artificial extraction method is not only time-consuming but also has big labor intensity and low efficiency. For chemical soaking extraction method, it cannot completely preserve the natural effect of plant fiber itself, if use chemicals improperly, it is likely to cause harm to the environment and the human body.

Work Principle:

The raw materials are put into the feed mechanism of automatic fiber extraction machine automatically or artificially, and then the feed mechanism sends the raw materials into the cutter. Due to the different rotating speed of the cutter and the feed mechanism, the combination of the cutter and the fixed blade breaks mesophyll or stems of the raw materials, separating the fibers out. The separated fibers fall down to the conveyor for the next process.

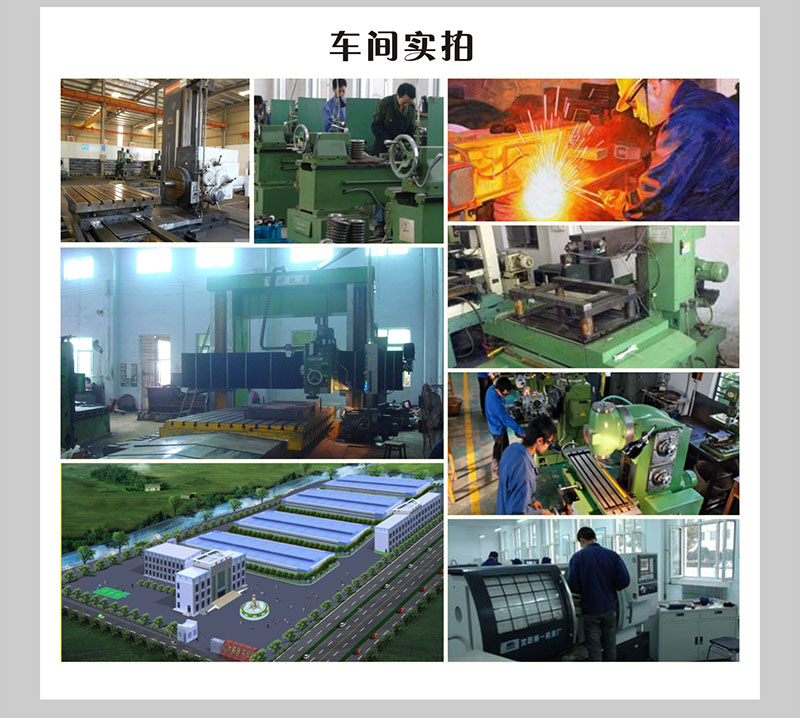

Factory Image:

Automatic decorticator run images:

Package:

About us:

1, Professional and strong engineer team available for customer;

2, Study and develop different type machine;

3, Renew the machine design year by year to improve its function;

4, More than ten years experience in this industrial area;

5, Good after service for helping customer to operate the machine

6, Receive patent certifications by self-create machine.

7, Export to all over the world directly.

Contact Us:

Sales: Nila Fung

Email: admin@weida-machinery.com.cn

Phone: +8513531093160

Skype: jacylee1008