Working conditions

a.Ambient temperature:-40ºC≤Ta≤+40ºC,-40ºC~+55ºC;

b.Standard atmospheric pressure: 80kpa(0.8bar)-1 lOkpa (1.1 bar), Normal oxygen content:

21%v/v;

c.Relative humidity: ≤95%;

d.Used in Zone 1 and Zone 2 hazardous areas where explosive gas mixture presents with T4 to T6 classification and combustible dust area zone 21 and 22;

e.Vibration and shake free;

f.Areas without gas or vapor which affects the performance of insulation;

g.Pollution grade: 3;

2. Compliances

IEC 60079-0:2011 EN60079-0:2012

IEC 60079-1:2007 EN60079-1:2007

IEC 60079-31:2008 EN60079-31:2009

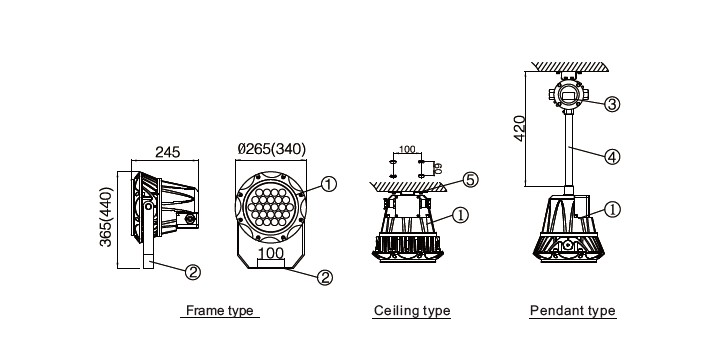

3. Structure

3.1, Shell using aluminum alloy die-casting molding (ADC12),with high-pressure electrostatic plastic sprayed surface,with anti-corrosion ability is very strong.

3.2, Using a cylindrical flameproof structure, reliable explosion-proof performance.Tempered glass is made of high strength tempered glass, fully meet the high energy shock resistance and thermal fusion requirements.

3.3,The exposed fasteners are made of stainless steel.

3.4, By introducing the device into the wire wiring cavity; steel pipe; lamps and are provided with a grounding screw shall be reliably grounded users.The shock effect is good, less heat, more safe and reliable.

4. Main technical parameters

Talbe1:

| Type | Rated Power(W) | Ex-mark | |

| -40ºC≤Ta≤+40ºC | -40ºC≤Ta≤+55ºC | ||

| 120 | II 2 G Exd IIB T6 Gb II2 D Ex tb III CT 80ºC Db IP66 | II 2 G Exd IIB T5 Gb II2 D Ex tb III CT95ºC Db IP66 | |

| 160 | II 2 G Exd IIB T5 Gb II2 D Ex tb III CT 95ºC Db IP66 | II 2 G Exd IIB T4 Gb II2 D Ex tb III CT 130ºC Db IP66 | |

Talbe2:

| Working Voltage | Cable O.D(φ mm) | Inlet Thread |

| 100V~300V AC 50/60Hz | Φ10~φ14 | 2×M25×1.5 |

5. Usage and Maintenance:

5.1 Check data on nameplate meet actual site conditions;

5.2 Check whether there are damage,distortion or loose on enclosure;

5.3 Workers of maintenance and repair shall be with professional knowledge and operation skills;

5.4 Conductors have been connected well,earthing stably;

5.5 In the repair shall be cut off before the explosion proof lamp power, open the cover off the power within ten minutes to ban open lamp, so as not to be high temperature scald; no off the power immediately after the cover with capacitor.

5.6 Electric gap,creepage distance and flameproof thread shall meet standard requirements during installation and maintenance;

5.7 During the installation, repair, should be properly protected flameproof surface, coated on the replacement of 204-1 type rust preventive oil.

5.8 The installation sequence

a)At the time of installation, remove the nut, remove the seal assembly.

b)Selected to meet the requirements of the cable length(Only the cables suitable for 80ºC ).

c)The cable sleeve seals (when the outer diameter of cable is more than Phi 11 in concentric circles, the seal in the round out). A sealing ring, Don't appear small cable wear big hole sealing ring phenomenon, so can not clamp sealing effect of explosion proof performance.

d)The cable and terminal connection, and connect the inner earth.

e)Press the sealing ring, the cable clamping, sealing is reliable.

f)The cap screw, and screw lock.

g)Connect the external.

5.9During the installation, repair, care should be taken to ensure the flameproof sealing pressing body and the shell and explosion-proof cable introducing device in order to avoid the influence of inlet or explosion-proof lamp,explosion-proof performance.

5.10 Should regularly check the explosion-proof lamp fastener looseness,sealing,corrosion Rubber seals harden or become sticky, wire insulation layer is greenish or carbonation, insulation if there Is deformation or scorch marks.Such as the discovery of the problem, should Be timely repair replacement. Regularly check the frequency of at least two times a year.Application of wet cloth to wipe the surface in dust environment.

English

English Español

Español Русский

Русский עברית

עברית Français

Français

Product quality protection

Product quality protection