86-371-60222952

Specification of Fully Automatic Square Bottom Paper Bag Making Machine With Rope Handle

Model |

ZM-450 |

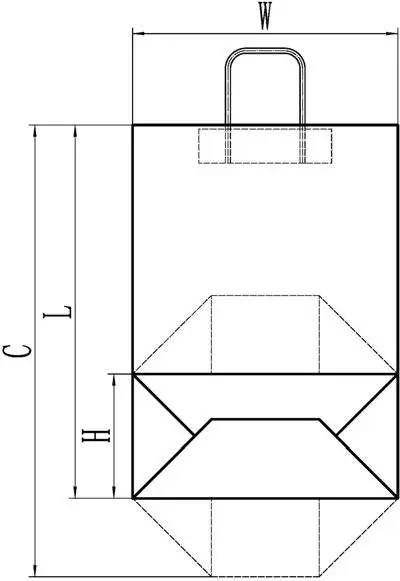

Bag Width(W) |

240-450 mm |

Bottom Size(H) |

90-180 mm |

Cutting Length(C) |

380-640 mm |

Max. Speed |

120 pcs/min |

Paper Roll Width |

700-1250 mm |

Max. reel weight |

800 Kg |

Max.Roll Diametr |

1200 mm |

Reel inner diameter |

76 mm |

Paper specification |

80-180 gsm |

Handle Rope Height |

100 mm |

Handle Rope Diameter |

4-6 mm |

Handle Patch Length |

190 mm |

Handle Patch Width |

40-50 mm |

Paper Patch Roll Diameter |

1200 mm |

Paper Patch Roll Width |

80-100 mm |

Paper Patch Thickness |

110-250 gsm |

Web edge control system |

Double photoelectric automatic correction control system |

Web tension control system |

automatic constant tension control system |

Air pressure |

≥0.12cmm, 0.6~1.2Mpa |

Driven motor |

Servo motor |

Power |

220V/380V,43KW |

Weight |

16000kg |

Dimension |

14500×6000×2500 mm |

Features of Fully Automatic Square Bottom Paper Bag Making Machine With Rope Handle

1. Touch screen is adopted for input control and machine status display, so as to finish machine correction easily.

2.Equipped with originally imported SIEMENS electrical system and servo motor drive, to make the machine run steadily.

3. Germany SICK photoelectric detector is used to track the material to be printed, reduce the adjusting time and improve production efficiency

4.Separate single-station unwinding rollstand with hydraulic lifting device; Convex-type inflatable shaft for loading material (or shaftless loading); Magnetic powder brake for unwinding and automatically constant tension controller for unwinding tension control; EPC web guide control system for material alignment; alarm function for reminding replacing material and stopping-machine device for detecting material broken.

5.The handle making component is an independent machine, which is driven by servo motor and synchronized with the main motor; handle length is adjustable according to bag size.

6.The cutting and gluing of paper handles are controlled by servo motors, as synchronous as the tub cutting of the main machine; contact rollers transfer pattern is adopted in gluing paper handles; vacuum suction pattern is adopted in transferring handles onto conveyer belt; handles are compressed onto the paper web with a series of pneumatic rollers, to ensure the pasting strength.

7.Adjustable forming mould structure (side sealing is above the forming mould); automatic glue-spraying device with automatic disengaging function is used for side gluing.

8.Rotary serrated cutter (or flat-blade cutter) with elliptical gears is used for cutting; the cutting length can be corrected by SICK photoelectric detector; Multi-layers bottom forming drum, center grippers, second tuck clamps, and drum grippers are adjustable for ease of changeover; automatic disengaging function (bottom gluing is prevented for empty feeding to avoid contamination to the surface of the drum).

9.Paper bags are delivered by belt, and collected at side workbench, which is easy for operations; automatic counting function.

10.Automatic lubricating oil supply system.

Packaging & Shipping

Packing Detail | Strong wooden case |

Mode of transportation | By sea,By Air, By Express |

Port of shipment | Main port in China mainland |

Our Services

*All of our machine have one year warranty,life-long maintance.

*Lowest price,best quality.

*24 hours online answer your questions.

*Delivery it to you as soon as possible.

Company Information

Zhengzhou Zomagtc Company Ltd. have been designing, developing, manufacturing

and marketing Machinery for more than 10 years. Firstly we mainly sever china mainland

customers. In order to adapt to world market development, now we do the exporting

business directly. After these years of development, we have high quality professional

teams,skillful talents, strong technical force, strong and independent research and

development capabilities, advanced productione quipment and a perfect after-sales

service system.

FAQ

Q1: How do you control the items quality?

A1: Each machine strictly tested one by one before shipping.

Q2: What is the delivery time?

A2: as normal 3-7 working days after confirm the payment

Q3: when we receive the box, find any items missing or defective, how should we do?

A3: please contact us ASAP, we will check and give you best solution soon.

Q4: What is quality guarantee policy?

A4: 12 months guarantee for all goods from our company, but we do not accept any broken by man.

Contact Us

Wendy

Zhengzhou Zomagtc Company Ltd

No.3 Dongfeng Road,Jinshui District,Zhengzhou,China

Website:www.electech.en.alibaba.com

Email:wendy@ superelec.cn

Skype/WhatsApp:+86 15737313646